Introduction to 3D Printing

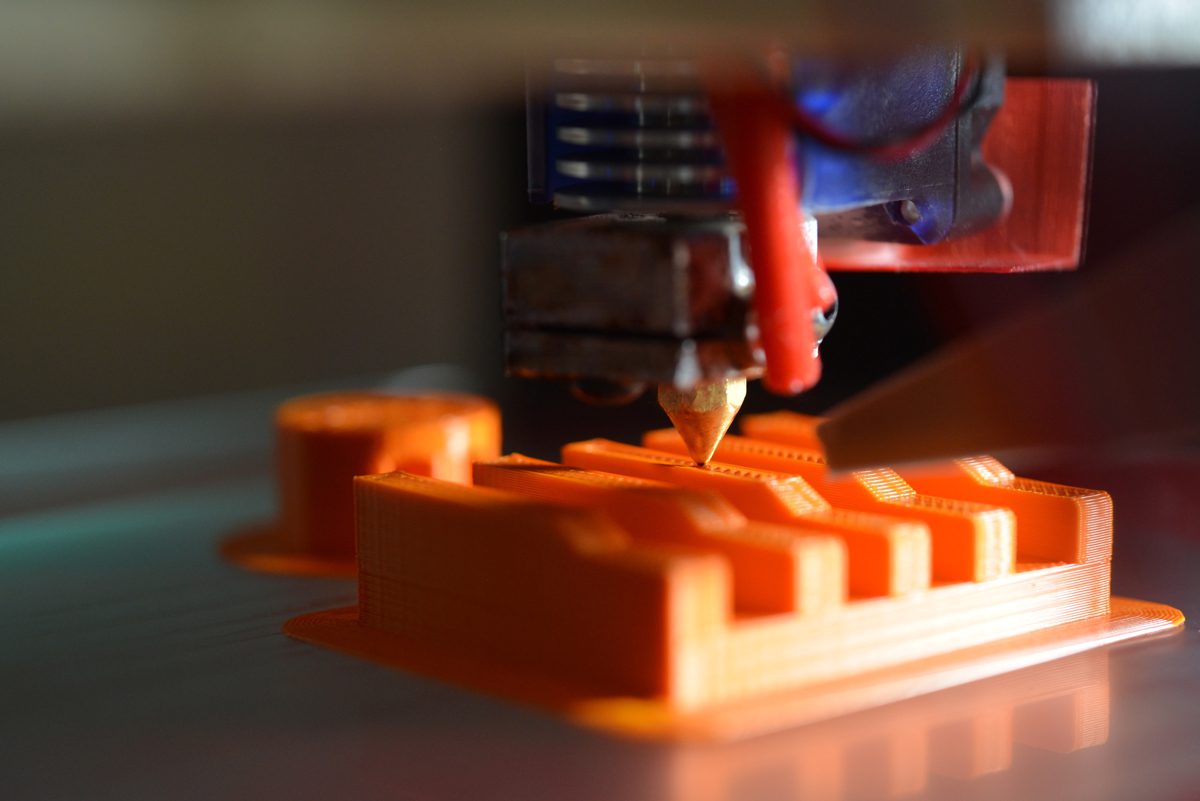

Three-Dimensional (3D) printing is a fascinating process where a digital design input acquires a physical form through additive manufacturing. This is achieved by building the object layer by layer, using materials such as plastics, metals, ceramics, and even biological materials. This technological advancement has added pace to the working process in the research and development sector in varied industries. However, this technology is still evolving and needs specific regulatory guidelines for large-scale manufacturing and mass production.

The History of 3D Printing

The history of 3D printing dates back to the early 1980s when Charles Hull invented the first 3D printing technology, called Stereolithography (SLA). In the following years, other 3D printing technologies such as Fused Deposition Modeling (FDM) and Selective Laser Sintering (SLS) were developed. By the 2010s, 3D printing had become more widely adopted, and the technology began to be used for a wide range of applications, including manufacturing, prototyping, medical, aerospace, and many more.

In recent years, the cost of 3D printing has dropped significantly, making it more accessible to small businesses and individuals. Also, the technology has been evolving and new methods of 3D printing are being developed, like binder jetting, digital light processing (DLP), and continuous liquid interface production (CLIP).

3D Printing in the Pharmaceutical Industry

Though it seems relatively advanced, the use of 3D printing in the pharmaceutical industry dates back to 1996.

3D printing has the potential to revolutionize the pharmaceutical industry in a number of ways. These include:

- Customized drug delivery: 3D printing can create customized drug delivery systems such as pills, implants, and patches that can release drugs at specific rates and in particular locations in the body.

- Customized dosages: 3D printing can be used to create pills with customized drug dosages.

- Personalized medicine: 3D printing can be used to create personalized medicine for individual patients based on their genetic makeup, medical history, and other factors.

- Rapid prototyping: 3D printing can rapidly prototype new drug delivery systems, enabling researchers to test different designs and materials before committing to large-scale production.

- Cost-effective production: 3D printing can create small batches of drugs at a lower cost than traditional manufacturing methods. This can be especially beneficial for drugs that are intended for use in rare diseases or developing countries.

- Reduced waste: 3D printing can help to reduce waste by only creating the exact quantity of drugs needed rather than producing large batches that may not be used.

3D printing – A Breakthrough for Personalized Medicine

India - “Pharmacy of the World” is the largest manufacturer of generic drugs. Manufacturing units of pharmaceuticals are well established in India. The process of drug manufacturing could transition from mass production to individual personalized treatments. Manufacturing drugs for patients has its own challenges, like managing adverse drug reactions and tolerability. 3D printing can produce printlets (3D printed tablets) that are individualized to a patient’s therapeutic need - dosage, drug combination, drug release profiles, and personal preferences - shape, size, texture, and flavor. This is a huge breakthrough in creating and offering personalized medicines.

Several studies have demonstrated the potential of 3D printing to create a diverse range of formulations, ranging from rapidly dissolving oral dispersible formulations, controlled release preparations, gastro-retentive tablets, suppositories, minitablets, medical devices, as well as flexible multi-drug combinations (i.e., polyprintlets). An example of a 3D-printed drug product approved by the US Food and Drug Administration (FDA) for human use is Levetiracetam in 2016. In February 2021, a drug manufactured through 3D printing to treat rheumatoid arthritis was approved for clinical study by FDA. Then, in March 2021, the Medicines and Healthcare Products Regulatory Agency (MHRA) proposed a new regulatory framework to enable the development of POC manufacturing and supply, including 3D printing technologies for personalized medicine production.

3D printing - A Strategy To Tackle Polypharmacy

Polypharmacy refers to the use of multiple drugs for different treatments simultaneously by the patient. This practice causes sub-therapeutic effects and toxicity due to drug interactions. The personalized drug delivery system, through 3D printing, could manufacture the drugs with accurate doses and even combine two or more compactable drugs. The pills manufactured are polypills, used to treat chronic metabolic disorders like diabetes, hypertension, and hyperlipidemia. Patient compliance decreases side effects, and desired therapeutic effects can be achieved using polypills to tackle polypharmacy. 3D printing is no less of a miracle in manufacturing anti-cancer drugs and immune suppressant drugs for autoimmune diseases as well.

Overall, 3D printing technology can greatly enhance the pharmaceutical industry by enabling the creation of new drug delivery systems, personalized medicine, and cost-effective production, among other benefits. Precision medicine is the future of personalized and optimized healthcare systems. Integrating 3D printing techniques in various parts of the healthcare sector will lead to continued advancement and enable personalized patient care.

As a career 3D printing offers varied opportunities which include roles in biomedical engineering, product development, drug delivery systems, pharmaceutical research and medical device manufacturing. The use of 3D printing technology in healthcare is expected to continue to grow, providing a dynamic and exciting field for professionals to pursue.

References:

- Innovative solutions for patients and pharmaceutical industry. International Journal of Pharmaceutics.

- Development of modified release 3D printed tablets (printlets) with pharmaceutical excipients using additive manufacturing. International Journal of Pharmaceutics. 2017;527:21–30.

- The Path to Personalized Medicine. N Engl J Med. 2010;363:301–4.

- 3D Printing Pharmaceuticals: Drug Development to Frontline Care. Trends in Pharmacological Sciences. 2018;39:440–51.

- 3D-Printed Isoniazid Tablets for the Treatment and Prevention of Tuberculosis—Personalized Dosing and Drug Release. AAPS PharmSciTech. 2019;20.

- Emergence of 3D Printed Dosage Forms: Opportunities and Challenges. Pharm Res. 2016;33:1817–32.

- Spritam (levetiracetam); full prescribing information. Spritam. 2015.

- Consultation on Point of Care manufacturing. Gov.uk. 2021

- The Advent of a New Era in Digital Healthcare: A Role for 3D Printing Technologies in Drug Manufacturing. Pharmaceutics. 2022 Mar 10;14(3):609.

- Customized 3D printed multi-drug systems: an effective and efficient approach to polypharmacy. Expert Opinion on Drug Delivery. 2022 Sep 2;19(9):1149-63.